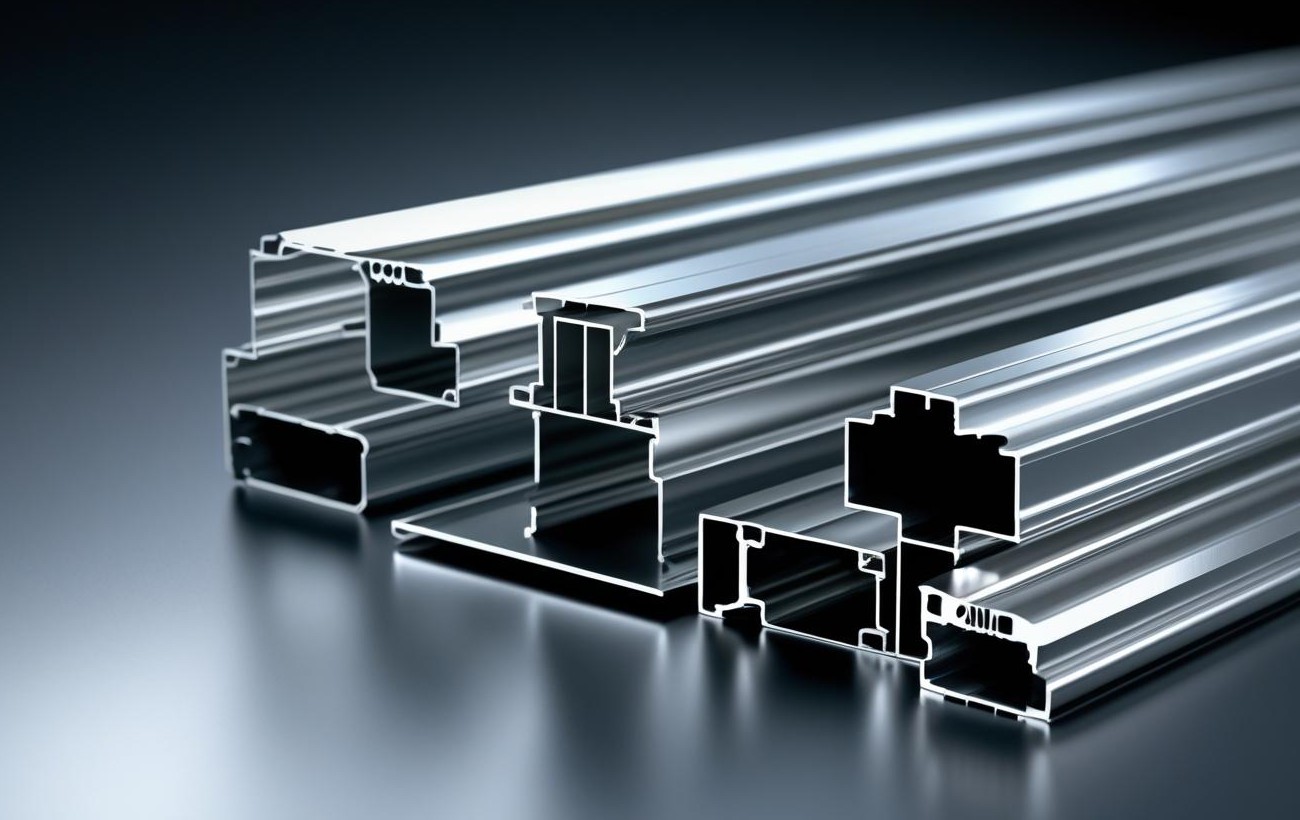

Extrusion is a continuous manufacturing process where heated material—typically plastic, rubber, or aluminum—is pushed through a die to form parts with a fixed cross-sectional profile. It enables efficient production of long, uniform components with consistent quality.

Application:

Extrusion is commonly used to produce:

Plastic tubes and medical-grade tubing

Wire insulation and cable sheathing

LED light covers and diffuser lenses

PVC or aluminum window and door frames

Automotive weatherstrips and sealing gaskets

Custom profiles for furniture and packaging

This process is ideal for high-volume production of durable, lightweight, and cost-effective parts with continuous shapes.

We specialize in custom aluminum extrusions designed to match your specific shape, strength, and structural requirements.

From extrusion and cutting to CNC machining, surface finishing, and assembly—we offer a complete solution under one roof.

With precise tooling and strict quality control, we ensure consistent extrusion profiles that meet industrial-grade standards.

Low MOQ, fast lead times, and international shipping make us a trusted partner for product developers worldwide.

Extrusion is widely used in industries such as construction, automotive, electronics, aerospace, and consumer products. It allows for the continuous production of complex cross-sectional profiles with high strength and lightweight properties. From window frames, heat sinks, and structural supports to decorative trims and precision tubes, extrusion offers an efficient, versatile solution for creating durable components with consistent quality and design flexibility.