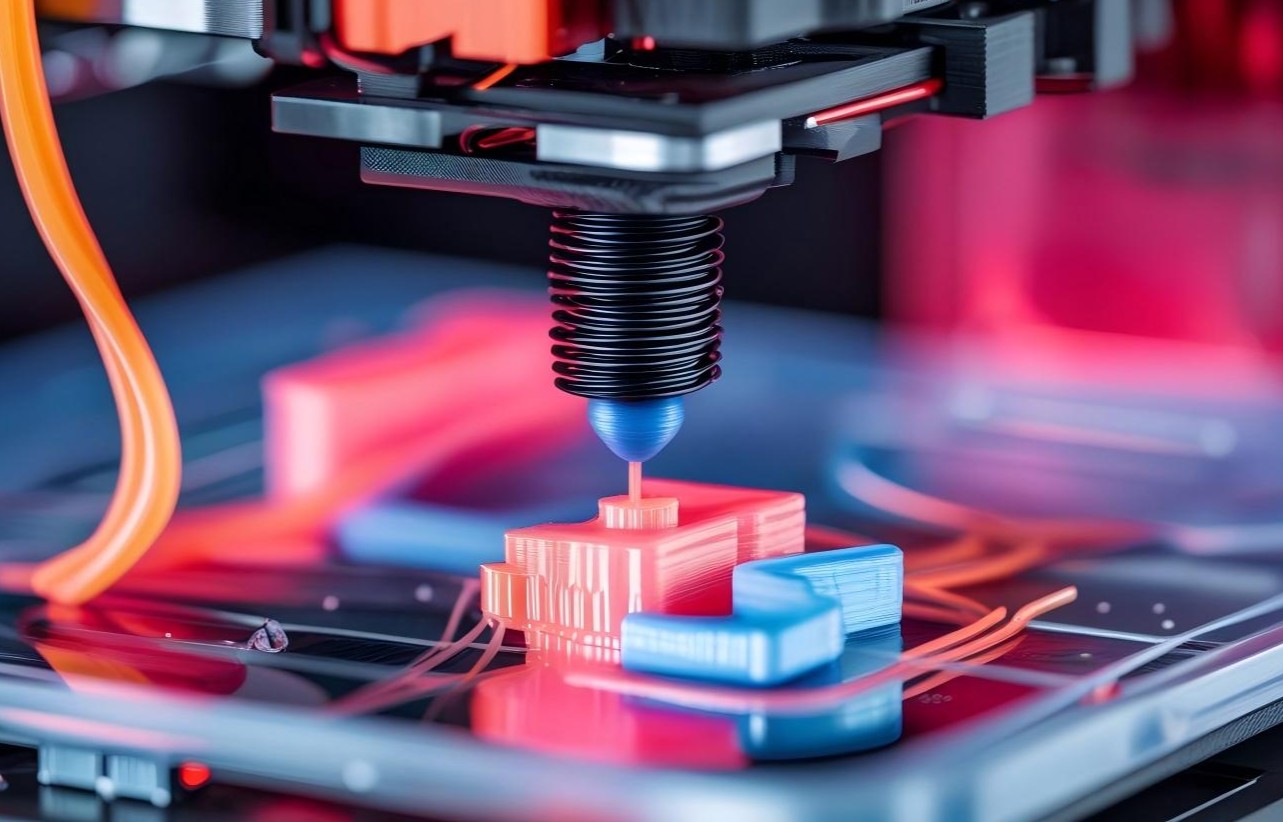

3D printing, or additive manufacturing, is a process that builds parts layer by layer from digital designs. It enables fast, flexible, and cost-effective production, especially for complex shapes and rapid prototyping.

Application:

3D printing is especially well-suited for producing complex, customized components with short lead times. Common product applications include:

Functional Prototypes – Used to test fit, form, and function before mass production.

Customized Enclosures – For electronics, IoT devices, and handheld equipment.

Medical Models & Devices – Such as dental aligners, surgical guides, and anatomical models.

Tooling and Jigs – Custom fixtures for assembly lines or quality checks.

With its design freedom and speed, 3D printing empowers innovation and customization like never before.

Speed up your product development with fast-turnaround 3D printing—ideal for early design validation and functional testing.

Easily create intricate geometries, internal channels, and undercuts that are difficult or impossible with traditional methods—no molds needed.

Choose from FDM, SLA, SLS, and more with materials like PLA, ABS, TPU, Nylon, and engineering resins tailored to your application.

Perfect for one-offs or small batches, 3D printing enables on-demand production with minimal setup cost and maximum design freedom.

3D printing is widely used across industries such as automotive, aerospace, medical, consumer products, electronics, and industrial manufacturing. From lightweight car parts and complex aircraft components to medical implants, customized tools, and product prototypes, 3D printing enables fast, flexible, and highly precise production, making innovative and customized designs more accessible than ever.