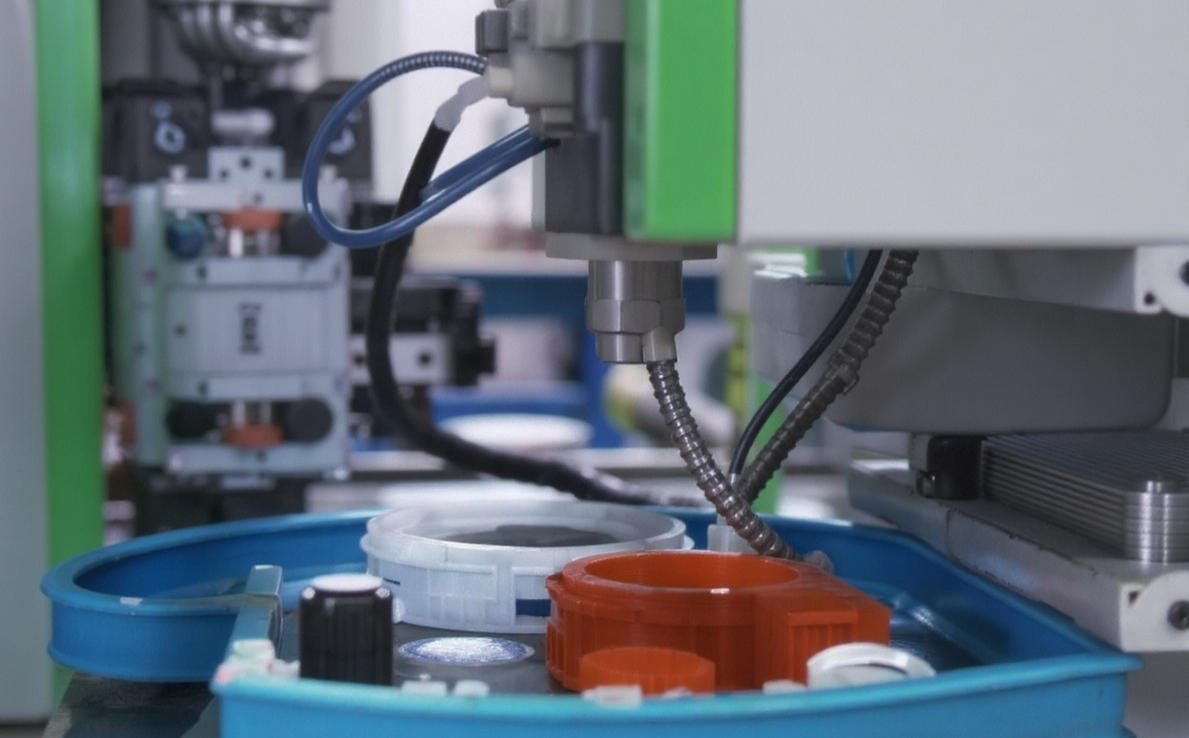

Injection Molding is a high-volume manufacturing process where molten plastic is injected into a metal mold under high pressure. The plastic cools and solidifies to form precise, durable parts with excellent surface finish. This method is ideal for mass production of complex and detailed components with consistent quality.

Application:

Injection molding is widely used to produce:

Electronic device housings (smartphone cases, tablet covers)

Automotive parts (dashboards, door panels)

Medical equipment components (syringe bodies, surgical instrument handles)

Household appliance shells

Consumer goods (toys, storage containers)

This process is perfect for producing large quantities of parts with complex geometries and tight tolerances, ensuring fast production cycles and cost efficiency.

Whether you need rapid tooling for prototyping or high-volume production molds, we provide scalable injection molding solutions tailored to your needs.

We support a broad range of thermoplastics including ABS, PC, PP, Nylon, TPU, and engineering-grade resins—meeting both functional and aesthetic requirements.

Our molds are built to tight tolerances, ensuring consistent part quality across every batch, from the first shot to the last.

With in-house mold making and optimized workflows, we offer competitive turnaround times and responsive communication.

Vacuum casting (also known as silicone mold replication) is widely used in industries like automotive, consumer electronics, medical devices, and product design. It enables fast, cost-effective production of small to medium batches with excellent surface finish and high detail accuracy. From prototype housings and functional parts to cosmetic models and low-volume end-use products, vacuum casting offers a reliable solution for quickly turning designs into high-quality physical parts.