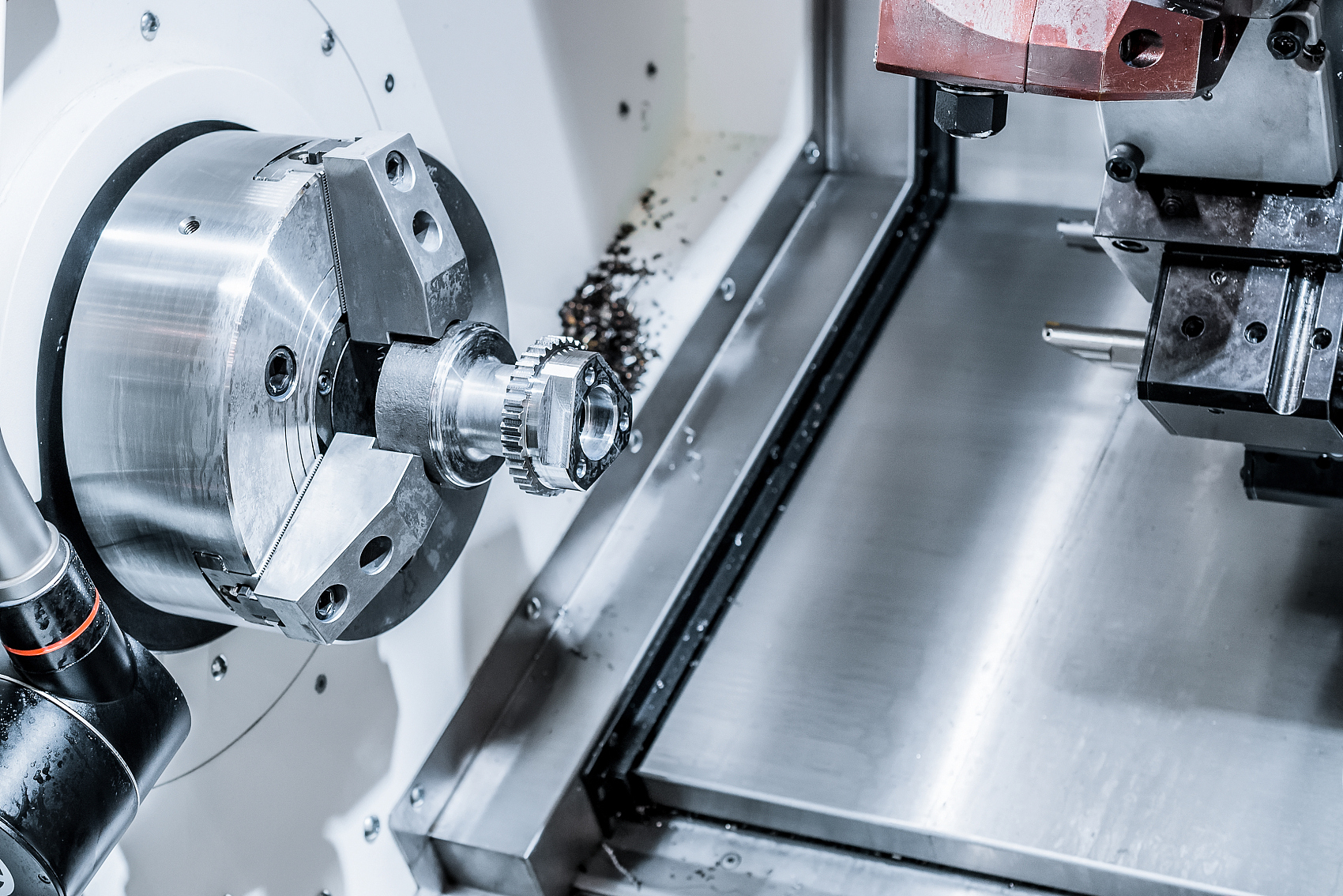

CNC is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. It allows for high-precision, repeatable, and automated machining operations such as drilling, milling, turning, and cutting on various materials.

Aerospace Components: Precision parts with tight tolerances

Automotive Industry: Engine parts, housings, and structural components

Medical Devices: Surgical instruments, prosthetics, diagnostic device enclosures

Consumer Electronics: Housings, connectors, and heat sinks

Robotics & Automation: Brackets, gears, and structural frames

Prototyping: Rapid production of functional and aesthetic prototypes for testing and validation

With CNC machining, manufacturers achieve consistent quality, reduced production time, and flexible scalability—from single-piece prototypes to full production runs.

With over 10 years of experience, we deliver high-accuracy CNC machined parts that meet tight tolerances and complex requirements.

From prototyping to low-volume production, we offer CNC milling, turning, and secondary processing — all under one roof.

Rapid turnaround with efficient workflow and DFM (design for manufacturing) support to help you speed up your product launch.

We serve clients across the US and Europe with reliable quality, clear communication, and on-time delivery every time.

CNC machining is widely used across industries such as automotive, aerospace, medical, robotics, electronics, and industrial equipment. It enables the production of high-precision components like engine parts, housings, brackets, surgical tools, and custom fixtures—delivering reliable performance, tight tolerances, and material flexibility for both prototypes and end-use parts.