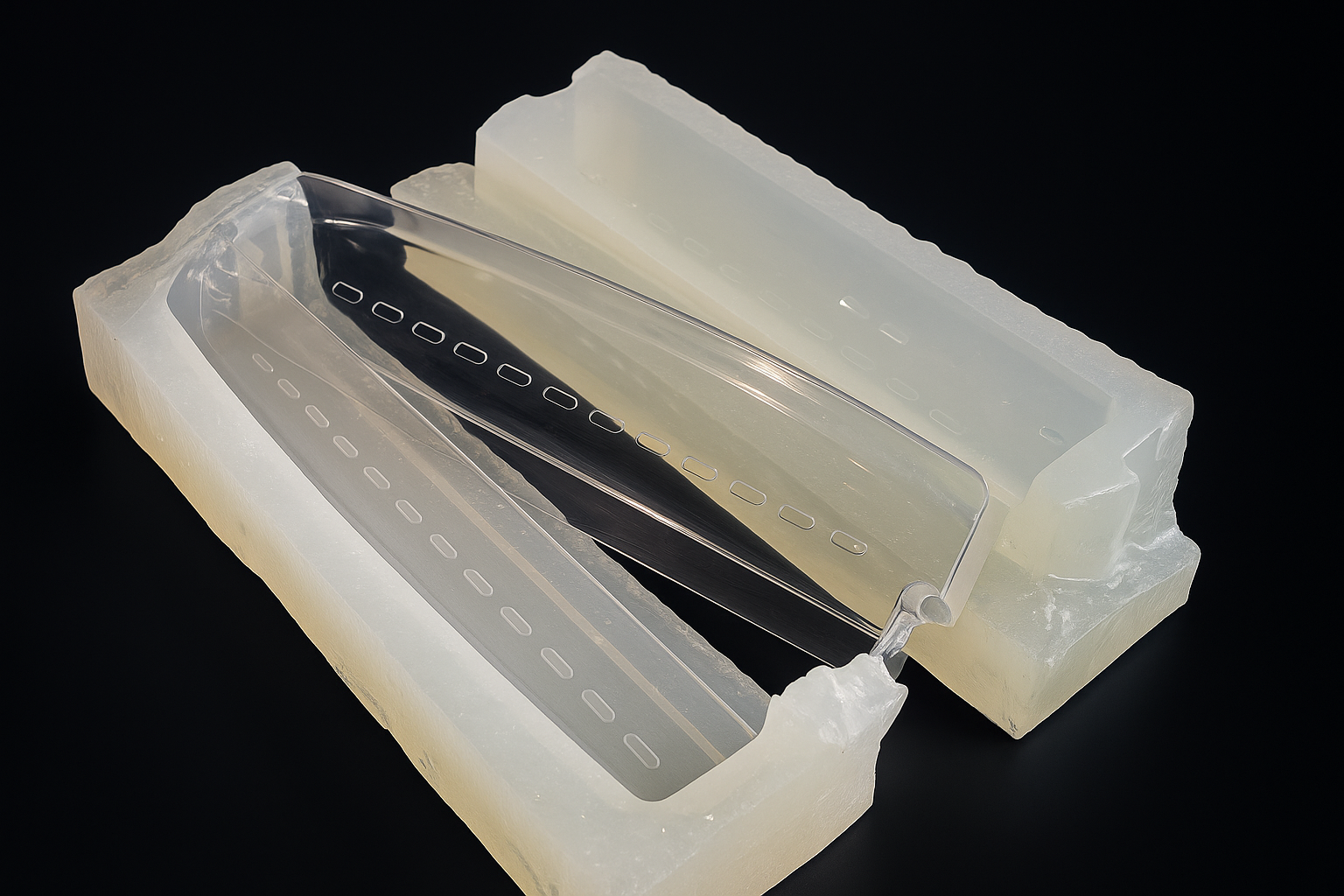

Vacuum casting is a low-volume manufacturing process that uses silicone molds and polyurethane resins to replicate high-quality plastic or rubber-like parts. The process is carried out under vacuum to eliminate air bubbles and ensure precise detail and smooth surfaces. It's ideal for short-run production, prototyping, and functional testing.

Application:

Vacuum casting is widely used to produce:

Consumer electronics housings ( smart speaker shells, wearable device cases)

Medical device covers and ergonomic grips

Automotive interior parts ( dashboard knobs, trim pieces)

Transparent light covers and display windows

Soft-touch components like seals, gaskets, and flexible buttons

This method is perfect for projects requiring high-quality surface finish, fast turnaround, and limited quantities before mass production.

Vacuum casting is ideal for small batches of 5–100+ units, bridging the gap between prototyping and molding without high tooling costs.

Mimic ABS, PC, PP, rubber, or even clear parts using high-quality polyurethane resins—great for functional testing and pre-launch models.

Using silicone molds, we replicate even the most intricate features with excellent surface quality, reducing the need for post-processing.

With short lead times and reusable molds, vacuum casting delivers high-fidelity parts quickly, ideal for validation, display, and low-risk production.

Vacuum casting (also known as silicone mold replication) is widely used in industries like automotive, consumer electronics, medical devices, and product design. It enables fast, cost-effective production of small to medium batches with excellent surface finish and high detail accuracy. From prototype housings and functional parts to cosmetic models and low-volume end-use products, vacuum casting offers a reliable solution for quickly turning designs into high-quality physical parts.