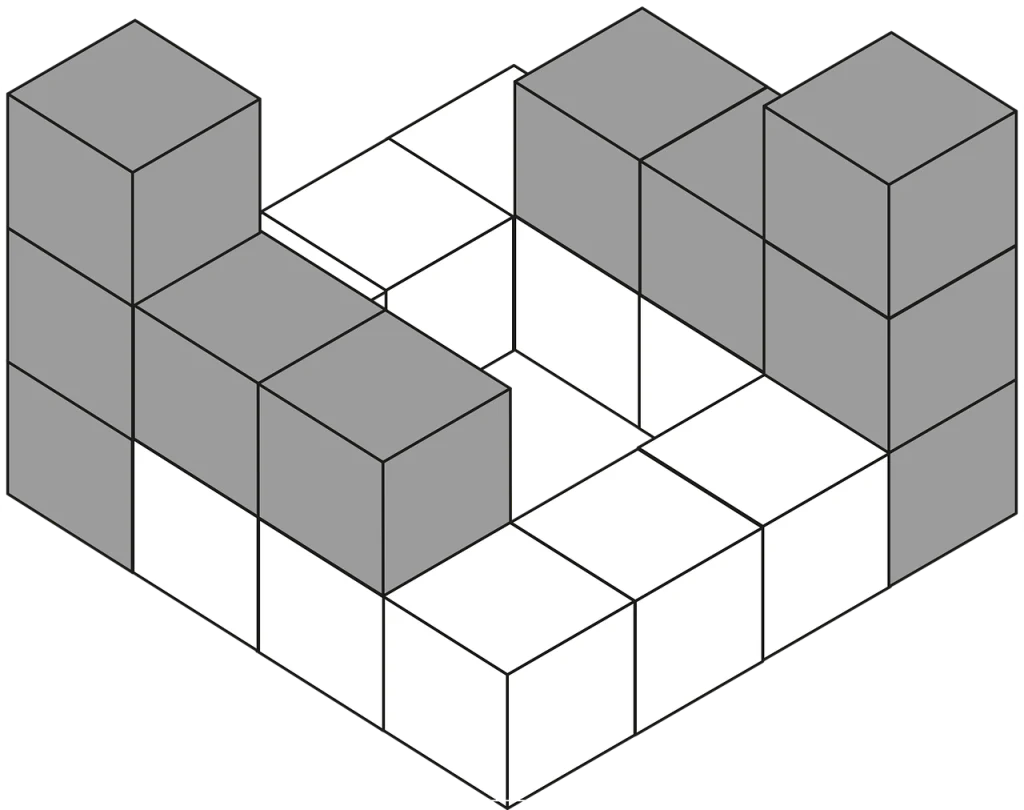

Injection Molding Mold Types Comparison

| Mold Type | Production Volume | Mold Material | Minimum Hardness | Ideal Use Case |

| Steel Molds | High | High-quality steel | 50-55 HRC | High-volume, high-precision, long-term production |

| Aluminum Molds | Medium | Aluminum | 40-45 HRC | Medium to low-volume production, cost-effective, fast turnarounds |

| Hard Alloy Molds | High | Hard alloy | 60+ HRC | High-precision, high-volume, wear-resistant applications |

| Silicone Molds | Low | Silicone | 20-30 Shore A | Rapid prototyping, low-volume production |

| Copper Molds | Medium | Copper alloy | 40-50 HRC | Medium-volume production, heat-sensitive parts |

Why Choose NexusProto for Injection molding Parts?

High Precision

Through high-precision injection molding, we ensure consistent dimensions and shapes for each part, meeting strict quality standards.

Fast Turnaround

Utilizing advanced injection molding technology, we provide fast production cycles and efficient delivery to meet high-volume manufacturing demands.

Cost-Effective Solutions

Ideal for large-scale production, reducing per-part costs and increasing manufacturing efficiency.

Wide Range of Materials

We offer a wide range of plastic materials, from general-purpose plastics to engineering plastics, catering to various application needs.

Injection molding Materials

General Purpose Plastics

pp

PE

PVC

Engineering Plastics

PC

PA

PET

Thermoplastic Elastomers

TPU

TPE

High-Performance Plastics

PTFE

PEEK

PPS

Composite Materials

GF-Nylon

CFRP