Precision | Performance | Speed in Automotive Manufacturing

High-Precision Manufacturing

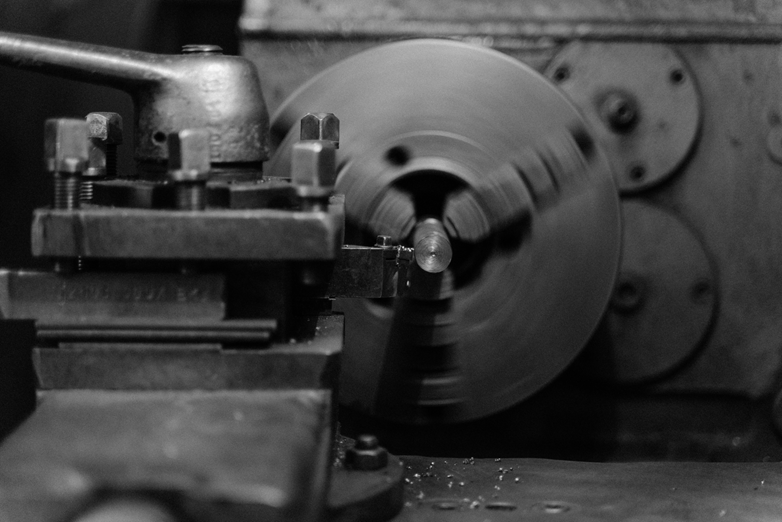

NexusProto is committed to high-precision manufacturing, ensuring that each component meets exact specifications. In automotive manufacturing, component fit and quality are critical for vehicle safety and performance. We utilize advanced CNC machining, laser cutting, precision casting, and injection molding techniques to maintain tight control over every stage of production, ensuring that each component produced is consistent and reliable.

This precision allows our components to fit perfectly during assembly, reducing rework and minimizing errors, thereby enhancing the overall quality of the vehicle. Additionally, through regular quality checks and precise measurements, we guarantee stable product quality, earning the trust of numerous automotive manufacturers.

Rapid Delivery

With rapid changes in market demand, shortened production cycles have become essential for automotive manufacturers. NexusProto offers integrated solutions from design to production, transforming design prototypes into finished products quickly. By optimizing production processes and using efficient manufacturing technologies, we shorten delivery times, helping our clients reach the market faster.

Our team excels at responding swiftly to client needs, leveraging flexible production capabilities and modern supply chain management to accelerate production without sacrificing quality. Particularly in the prototyping phase, we offer ultra-fast delivery, enabling automotive manufacturers to perform design validations and testing in the shortest possible time, significantly improving R&D efficiency.

Innovative Solutions

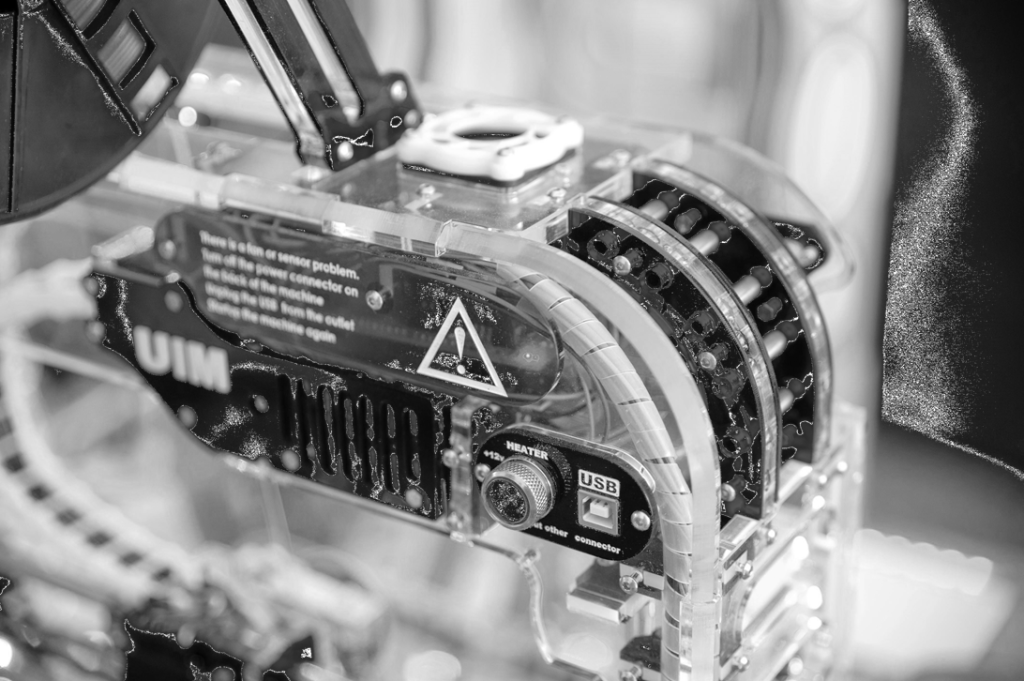

NexusProto continuously invests in technological innovation, actively introducing new technologies to advance manufacturing capabilities. We employ additive manufacturing (3D printing), composite materials, smart automation, and virtual simulation to provide future-ready automotive component solutions. For instance, with 3D printing, we can quickly create complex geometric shapes, achieving designs that traditional methods cannot fulfill.

This capacity for innovation allows us to meet evolving market demands while helping automotive manufacturers achieve breakthroughs in design and performance. Our innovative technologies enable weight reduction, durability, and aesthetic enhancements while significantly reducing prototyping costs, providing clients with more competitive solutions.

Customized Solutions

Each automotive manufacturer has unique needs, and NexusProto’s customized services deliver components and solutions tailored to those specifications. We work closely with clients to create custom components that match the unique characteristics of their vehicles. From seat frames to sensor enclosures, interior décor to body structures, we adapt flexibly to different requirements.

Our team of experienced engineers can quickly understand client needs and recommend optimal solutions. Whether for small-batch production or high-end, specially designed parts, we provide efficient customized manufacturing services, creating unique products for each client.

Common Automotive Components can be produced

Automotive Prototypes

Exterior Prototype Parts

Interior Prototype

Functional Test Prototypes

Automotive Electronics Components

ECU – Electronic Control Units

Sensors and Connectors

Automotive Thermal Management Systems

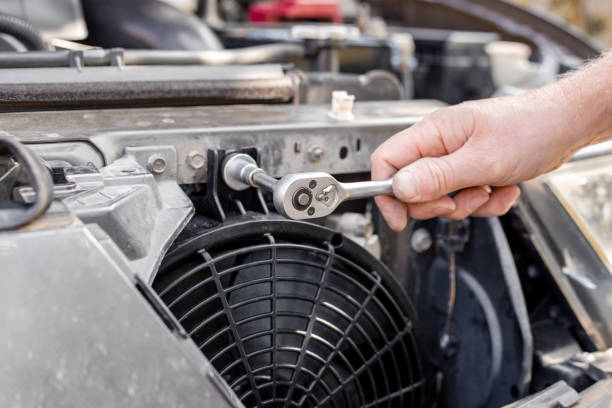

Radiators

Cooling System Components

Automotive Parts

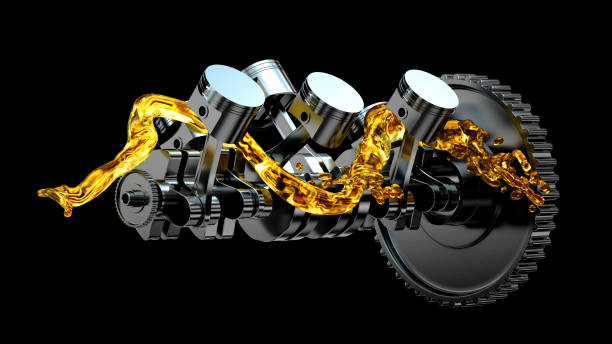

Engine Components

Braking Systems

Body Structural Components

Interior Components

Automotive Lighting

Automotive Drivetrain Components

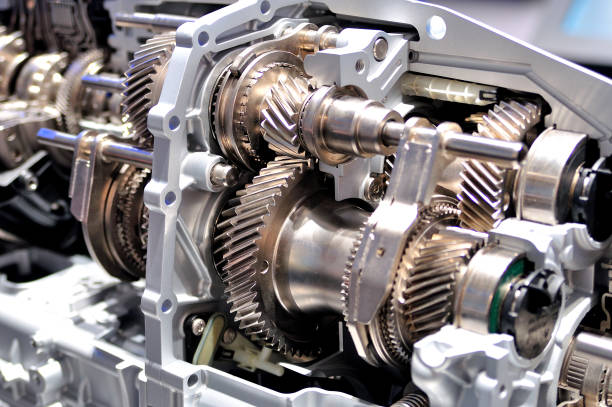

Transmission Components

Drive Shafts

Automotive Suspension Components

Springs

Shock Absorbers

Automotive Accessories and Attachments

Roof Racks

In-Car Navigation Systems

Composite Materials Components

Lightweight Body Parts